Commitment to quality

KICS: Supporting manufacturing

Manufacturing at the KITZ Group is based on providing the products our customers need when they need them, in just the right quantities and with better quality. Manufacturing based on this concept is supported by our innovative production system, KICS (KITZ Innovative and Challenging System). Through creating one product at a time in process order at the timing needed, KICS thoroughly eliminates lags and waste throughout the process from ordering through delivery, enabling reduced costs and shortened lead times.

The KICS concept is a part of KITZ SCT’s manufacturing system as well, aiming to provide our customers with the products they need at the perfect time.

Quality assurance system in manufacturing

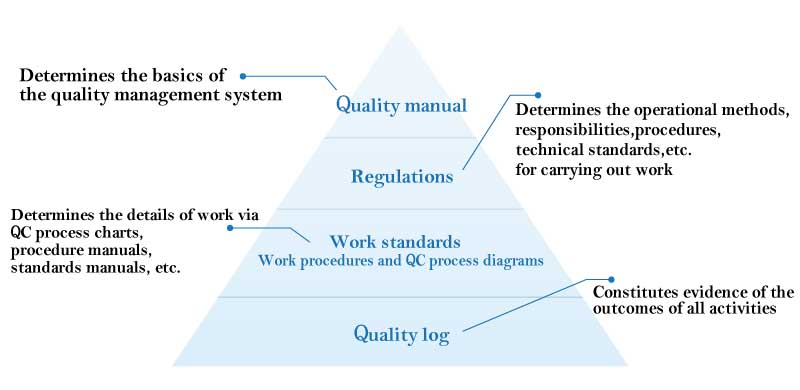

At KITZ SCT, all production bases in Japan and overseas (Nitta SC Plant, China Kunshan Plant) are ISO 9001 certified. Further, in Japan (Nitta SC Plant), ministerial exam accreditation has also been received under the High Pressure Gas Safety Act. In this way, we have established a quality assurance system based on ISO 9000, as a system operated and maintained throughout the production process in every department.

Production network realizing high quality and low cost

We have worked hard to create a production system delivering products which will lead to customer satisfaction in everything from quality to lead time and servicing. In Japan, the Nitta SC Plant is a development base and central production plant for high added-value products, as well as a leader with regard to the China Kunshan Plant, which started production in 2004.

Further, KITZ SCT has a BCP (Business Continuity Plan) intended to handle the risks of major disasters and unforeseen circumstances. The China Kunshan Plant plays a role in ensuring that products can be delivered to customers whenever possible. In addition, in order to provide customers with the same high-quality products as at the Nitta SC Plant, the China Kunshan Plant adopts equivalent facilities and production lines. With an integrated production system throughout processes as well as facilities, it produces mainly general-purpose products. In the inspection process as well, certification inspectors conduct inspections in order to ship only products of the same high quality as those from the Nitta SC Plant.

Nitta SC Plant

China Kunshan Plant

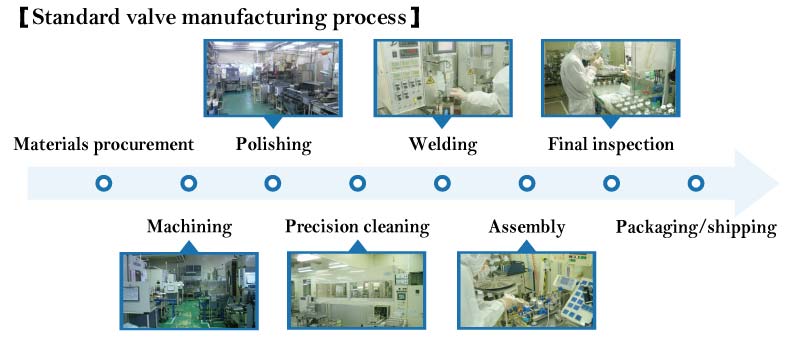

We realize quality stability with integrated production systems and we continue to provide high-reliability products

The KITZ Group is founded on integrated production: KITZ SCT performs material procurement(receiving), completion inspection, to shipment in-house. In particular, the polishing process including electro-polishing is positioned as our core technology, and our own polishing facilities are designed in-house to establish a quality system and realize diversified production of small-volume products under an integrated system.

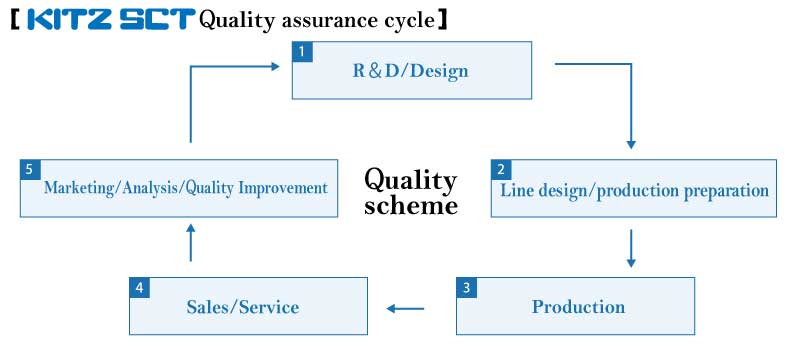

KITZ SCT quality framework

From development and design, the start of manufacturing, on, we reflect existing and new technologies in our products. As well, by reflecting these technologies in the production process as well as the products themselves, we realize product design with an eye to production convenience. This enables us to construct stable processes, which in turn lead to high-quality products.

In addition, we constantly conduct improvement based on quality information from customers and the market, working to further enhance quality.