Highlighted products

Find a product

PFA tube fusion welding fittings

These fusion welding fittings support prevention of the leaks caused by higher temperatures and concentrations of chemical liquid in semiconductor manufacturing process piping.

Features

No leakage, clean, lightweight and compact

No need for retightening and no concerns about leakage, since the end faces of the fitting and tube are completely sealed by butt fusion welding.

The fusion welded parts have higher strength than the tube and will not break or rupture.

There is no sliding part on the inner surface of the connection, providing excellent particle characteristics.

High heat resistance is achieved, preventing loosening or leakage due to thermal cycling.

Enables easy shortest-distance fusion welding

The newly equipped boss enables fusion welding by customers even when dimensions permit no clamping allowance, enabling compact piping layouts.

*The shortest-distance cutting jig and shortest-distance fusion welding clamp jig for PMW fusion welding machine are required.

*Since 1 1/2 has no boss, shortest-distance fusion welding is not possible.

Sleeve can be press-fit directly

With a longer tube, a sleeve press-fit type fitting can be directly installed, enabling shorter installation time and more compact piping design. Clamping the boss with a press-fit jig stabilizes the orientation while press-fitting, making it easy to insert the sleeve straight and preventing installation errors.

* The press-fit jig is to be prepared by the customer.

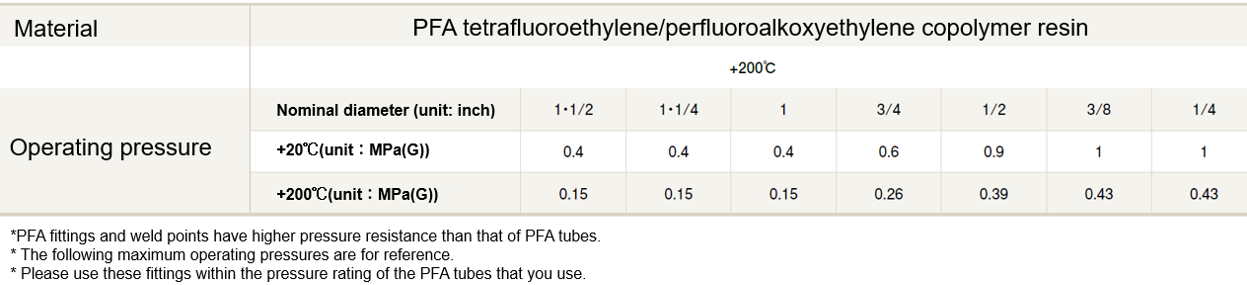

Main specifications

For details, see the product catalog. Access is also available via the button below.