Development and Production System

concept

The KITZ SCT R&D concept

At KITZ SCT, in order for the development, sales, and production departments to work together and consistently provide highly reliable products leading to customer satisfaction, we actively conduct new technology research surveys.

Strengths of the KITZ SCT development and production systems

-

POINT

Manufacturing capable of handling not only general-purpose products but also customer requests for special and high added-value systems

-

POINT

Proprietary technology responding to customers' trust worldwide

-

POINT

Product development constantly evolving through world-class technological capacity

point 01

Manufacturing capable of handling not only general-purpose products but also customer requests for special and high added-value systems

At KITZ SCT, we create fluid control devices boasting safety, durability, and reliability. We have constructed a proprietary development and testing system which continues to produce high added-value products. As a company focused on development, KITZ SCT guarantees the continued provision of products in response to customer demand, based on a spirit of challenge.

point02

Proprietary technology responding to customers' trust worldwide

Based on market-in thinking, in order to provide our customers with high-quality, original products, the KITZ Group works as one to cultivate product and production technologies enabling higher functionality and ultra-precision, improving technological capacities in various fields.

Realizing superb thermal uniformity

We possess the optimal heating technology for the stable supply of vaporized or sublimated chemical compounds to the use point, as well as for ensured thermal uniformity reducing the accumulation of byproducts within valves.

Ultra-high pressure valve series for hydrogen stations

We conduct product development in accordance with the law as a high-pressure gas certified business, developing products requiring ultra-high pressure technology which are used in everything from the semiconductor industry to hydrogen filling stations for fuel cell vehicles (FCV).

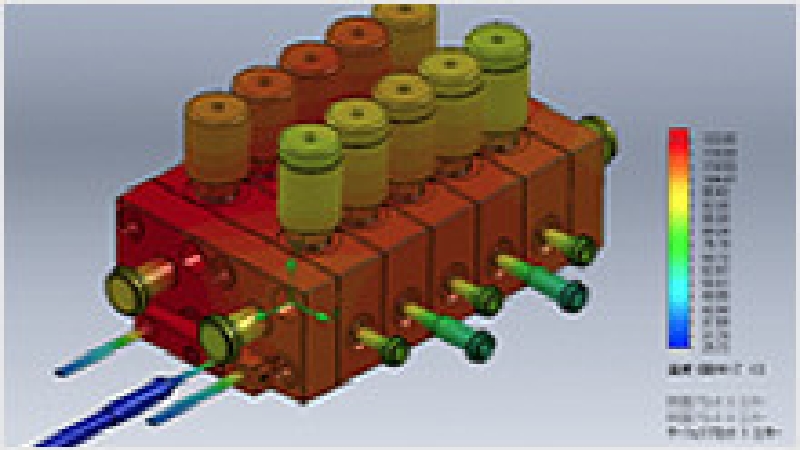

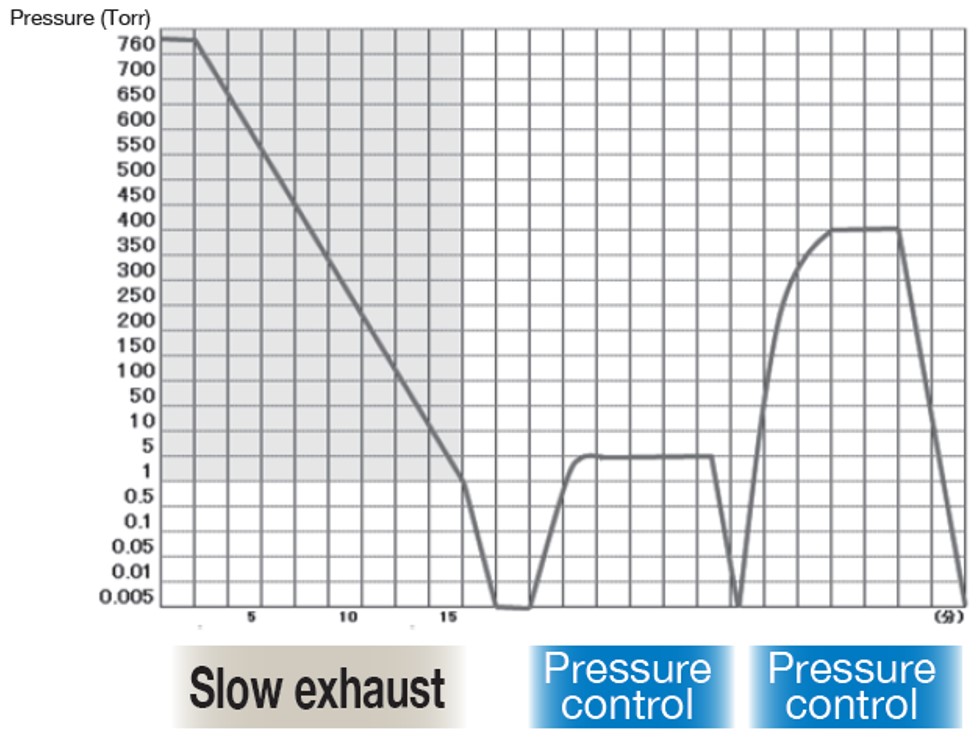

Realizing wide-ranging pressure control

In order to realize wide-ranging pressure control from high to low vacuum areas, we have created optimal pressure control technology melding our control technology and our proprietary mechanism technology.

point 03

Product development constantly evolving through world-class technological capacity

APC butterfly valves

Our proprietary structure, in which the seat ring and flapper activate continuously, realizes valve open/close, slow exhaust, and pressure regulation functions in a single valve. As well, the flapper O-ring durability has been notably improved.

HOT valves

Through our proprietary heating structure, based on heaters mounted on the valve body exterior and bellows interior, cold spots can be eliminated and byproduct accumulation reduced. This extends maintenance cycles caused by equipment stoppages, improving equipment operating rates.

HOT gate valves

Individual temperature control of the heaters on the body exterior and valve body interior ensures excellent thermal uniformity, reducing the accumulation of byproducts and extending the maintenance cycle. As well, a non-sliding structure is used to reduce the generation of particles when the valve opens and closes.

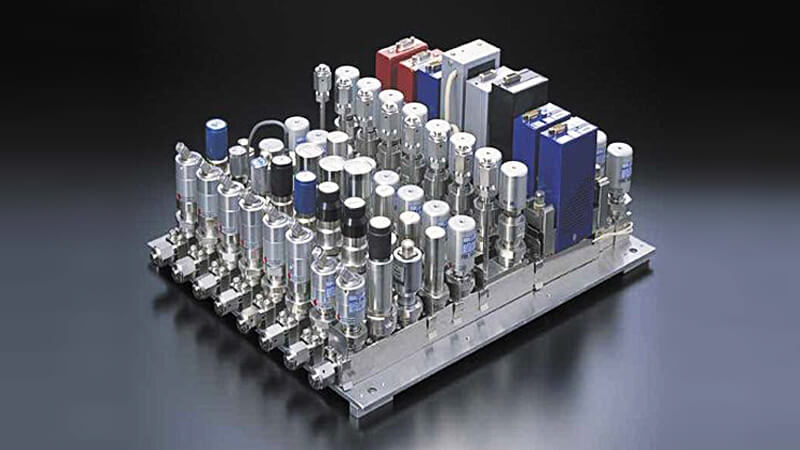

Integrated gas system

Adopting the KITZ SCT proprietary B-SEAL (center-lock), this gas system has a minimized footprint and excellent maintainability. B-SEAL (center-lock) enables rapid replacement of devices such as valves with a single nut, like racing car tire changes.

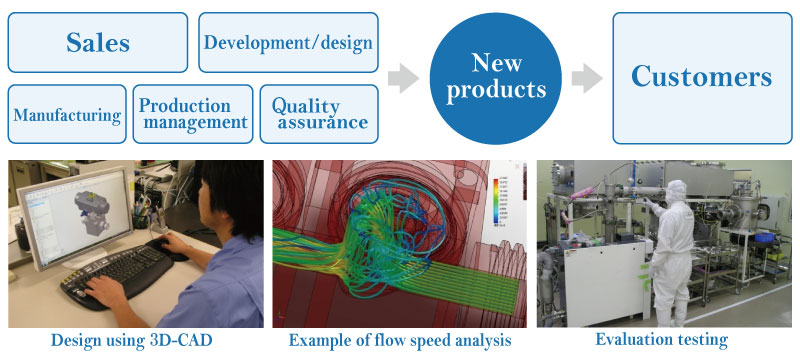

KITZ SCT development system

At KITZ SCT, we have integrated development and design, quality assurance, production management, manufacturing, and sales toward the development of new products. By developing new products from various angles, we rapidly provide products suited to customer needs. As well, we are constantly developing new products, through the adoption of new technology and other approaches.

KITZ SCT development chronology

1984 to 2000

Ultra high purity gas fittings

Ultra high purity gas valves

Integrated gas system

- October 1984

-

SCF automatic welding fittings

- April 1988

-

KD diaphragm valves

- December 1988

-

SCM/SCL automatic welding fittings

- February 1991

-

CVC metal gasket surface seal fittings

- March 1993

-

IBX Series large-diameter bellows valves

- April 1993

-

IB bellows valves

- June 1993

-

IVWF vacuum butterfly valves

- October 1993

-

IVB L-type vacuum bellows valves

- November 1994

-

IVBH L-type vacuum bellows heated valves

- October 1996

-

UXG square vacuum gate valves

- November 1996

-

WD diaphragm valves for liquid gas

B-SEAL valves - February 1997

-

Integrated gas system

- November 1999

-

RD high-pressure diaphragm valves

- August 2000

-

C-SEAL valves

2001 to 2015

Resin valves

Valves for hydrogen stations

PCA APC butterfly valves

- August 2002

-

TB welded fittings

- November 2002

-

BZD clean butterfly valves

- October 2003

-

Chemical feeders and eFLOW® antistatic equipment

- November 2003

-

DWP type pure water pressure boosting units

- November 2004

-

FCD PFA diaphragm valves

- February 2008

-

VLD diaphragm valves

- April 2010

-

Gas supply system products for MO-CVD

- November 2011

-

BRW NW flange ball valves

- August 2012

-

Products for hydrogen stations

- December 2013

-

FCDT high-temperature resin valves for 200°C

- February 2015

-

PCA APC butterfly valves

- October 2015

-

TBN PFA tube fusion welding fittings

NRHD8 large flow diaphragm valves for 20.6 MPa - November 2015

-

NRD4 Cv0.1 diaphragm valves

2016 on

NRD high-pressure diaphragm valves

PCW automatic control butterfly valves

- March 2016

-

ZCD8K gas-contact 250°C seat replaceable diaphragm valves

- August 2016

-

VLD4D diaphragm valves for 1.45 MPa

- September 2016

-

NDHD8 diaphragm valves for 2.0 MPa

- January 2017

-

KD diaphragm valves with relief function

- February 2017

-

NRMD8C 20.6 MPa diaphragm valves

- June 2017

-

KDS SCV® submersible valves

- April 2018

-

NDD4M diaphragm valves for 2.0 MPa

- June 2018

-

PCW automatic control butterfly valves

- July 2018

-

TDF high speed, high durability valves

- October 2018

-

XD12 diaphragm valves

- January 2019

-

TDS SCV® submersible valves